Community Metalwork

So, the first mechanical design, despite its low cost, turned out to be impractical. But it may eventually fly thanks to the good folks at groupDIY.com who keep coming up with candidate enclosures. In fact, community is an important element of this project because DIYers and music makers are the end users, and it was a community member (Kid Squid) who came to my aid when I was trying to visualise a new enclosure. He very kindly offered to create a number of 3D renderings of a new enclosure despite being up to his neck in work (thanks Steve).

To put this into context I soon realised that good old plug in modules made great sense in terms of simplifying the rats nest of wiring created by the original design. It would confine the wiring to two areas; first from the rear panel to a motherboard, and second from the plug in module front panel to its main board. It also meant a great deal of flexibility of mixer design was possible. OK, it would be more expensive but at least it was viable and I had already designed most of the necessary parts. The big question was what size/shape should it be?

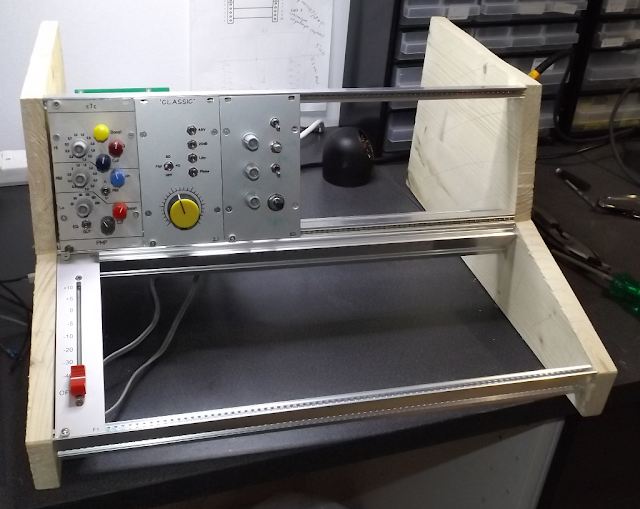

The simplest and cheapest answer is a 3U Euro-rack enclosure exactly like the ones I used for the Lunch-box project. But this does not give you much panel room. The standard EZTubeMixer modules are 70mm wide and six of these will fit across a 19 inch Euro-rack. You cannot fit a whole lot of controls on a 3U by 70mm front panel and if you want slider faders as well, forget it. So initial thoughts turned to a 3U Euro-rack plus a fader nose at the front. To keep costs down, standard extrusions would be used and the only custom part would be the two end cheeks. The whole would be mostly an open frame that could be clad in wood if required. And this is where Kid Squid came in. We started with a very rough wooden model I built one weekend:

Which Steve turned into this:

And this:

And finally this:

I then contacted SRS in the UK who designed a pair of custom cheeks based on this design. We tweaked it so the top panel could be a standard SRS solid screening panel and this was the result:

Now we have a very flexible enclosure. Total cost for the pair of side cheeks, the extrusions and top plate is around £200. The big question is what do we put in it? Another question for the community.

Comments

Post a Comment